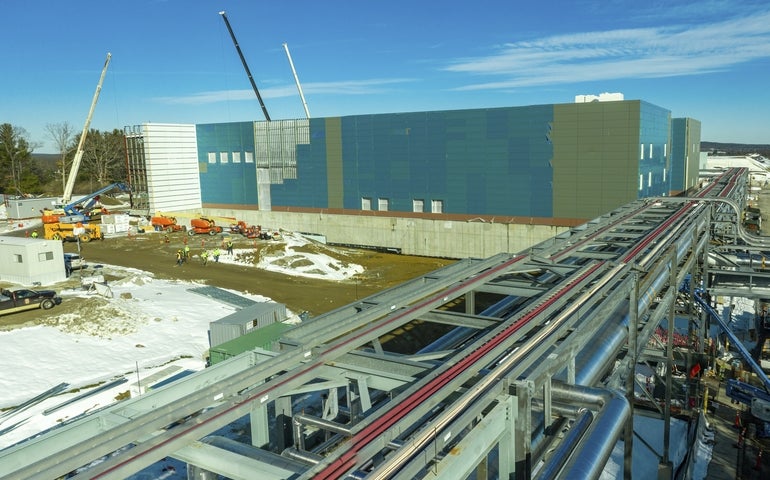

A 244,000-square-foot expansion at Bristol Myers Squibb’s Devens facility will add to the drugmaker’s efforts to fight cancer using specialized technology.

Representatives for the New York-based company gave a virtual tour Tuesday of how the company’s CAR-T cell therapy, which uses genetically modified cells, works to help a patient fight cancer. The Devens facility, which could start operations by around the end of the year, will make Breyanzi, a treatment for lymphoma patients and Bristol Myers Squibb’s first CAR-T cell therapy.

The technology works by taking a patient’s white blood cells, part of the body’s immune system, and modifying them to attack cancer cells. That modification process, which is carefully monitored and takes weeks, will take place at the expanded Devens site and a few other Bristol Myers Squibb locations. A patient then receives an infusion of those modified cells.

“I’m really excited about what cell therapy has to offer,” said Krishnan Viswanadhan, a senior vice president for Bristol Myers Squibb’s global cell therapy franchise.

Company officials said a good portion of the CAR-T cell manufacturing capability will be thanks to the Devens site, which is an expansion of an already significant campus for the drugmaker. The technology remains new, with Breyanzi winning U.S. Food and Drug Administration approval in early February.

“It’ll have the latest and greatest technology,” Shehal Patel, a vice president and global head of Bristol Myers Squibb’s cell therapy manufacturing, said of the Devens site.

The Devens site is expected to add hundreds of jobs. Workers in CAR-T cell therapy typically have experience in the pharmaceutical or biotechnology fields and pass through a rigorous training program, Patel said. By the end of this year, the company anticipates to have more than 2,000 workers in cell therapy manufacturing across its sites.

The work is highly specialized, officials said. The process takes weeks, needing to be personalized for each person’s unique cells, and requiring isolating the right cells, freezing them and diluting them for shipment back to the patient. All the while, lab workers go through what the company said is more than 500 chain-of-identity points to ensure cells are accurately and safely tracked.

The Devens site, which already spanned 700,000 square feet, also includes drug manufacturing for Orencia, a biologic therapy for rheumatoid arthritis, and Empliciti, an immuno-oncology medicine.