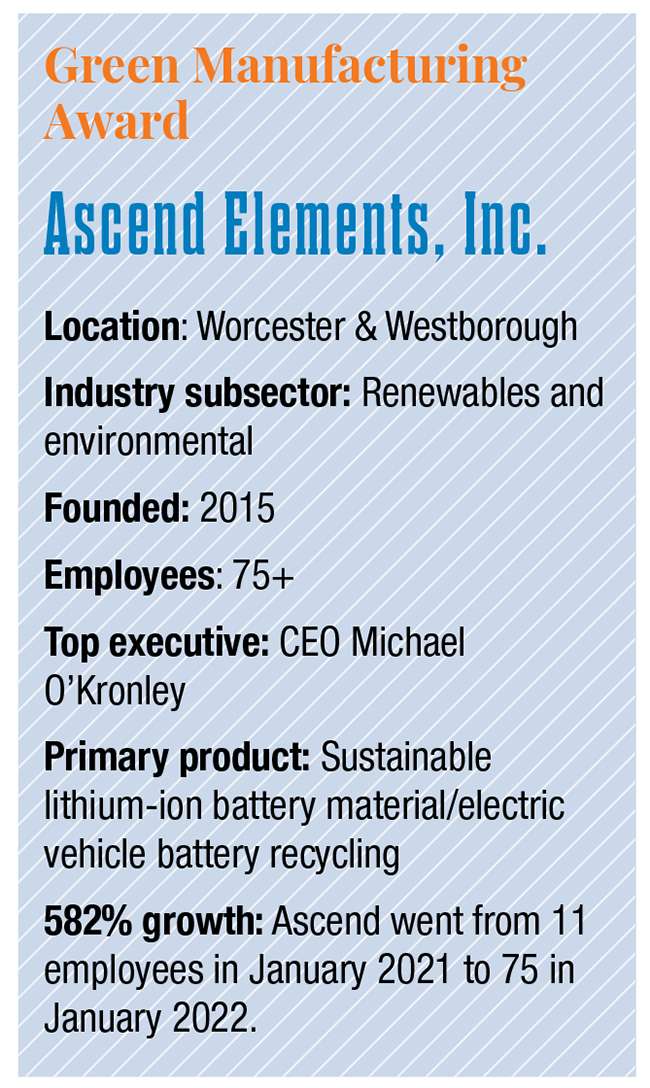

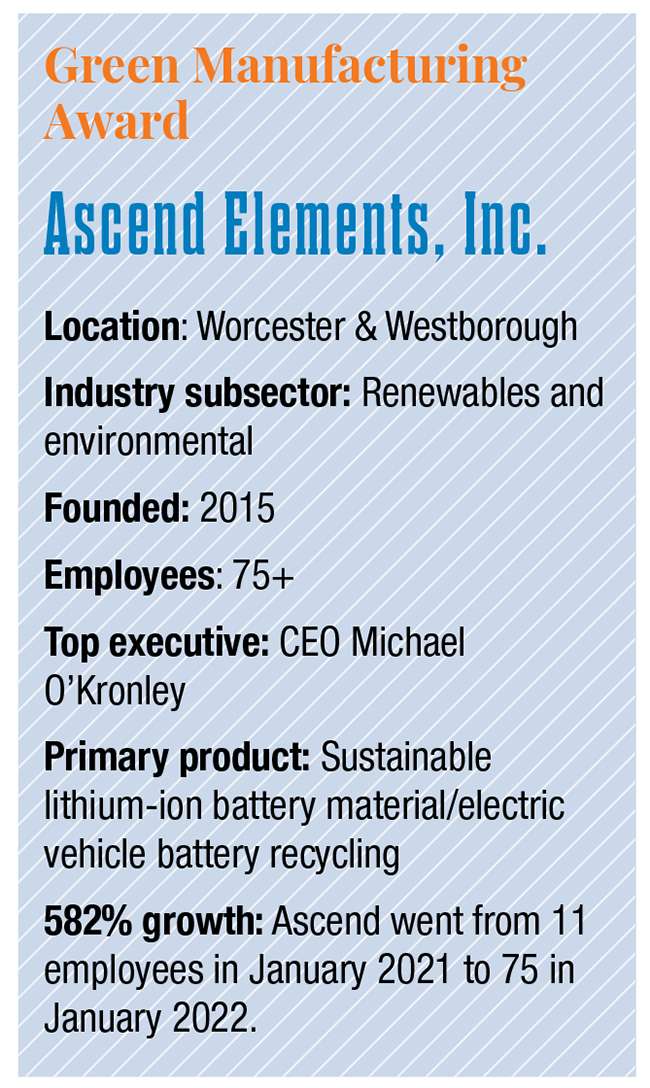

Manufacturing awards: Ascend Elements is at the forefront of a greener future

Photo | Courtesy of Ascend Elements

Michael O'Kronley, CEO of Ascend Elements

Photo | Courtesy of Ascend Elements

Michael O'Kronley, CEO of Ascend Elements

Founded in Worcester and headquartered in Westborough, Ascend Elements is rapidly growing domestically and gaining notoriety internationally due to its hydro-to-cathode system, which transforms used lithium batteries and manufacturing scrap into high-quality batteries geared towards the electric vehicle industry.

Ascend, previously known as Battery Resourcers, was conceptualized at Worcester Polytechnic Institute when professor Yan Wang started doing research on how to recycle batteries in 2011, which led to the creation of the company in 2015.

“Our mission is to take all spent lithium ion batteries and return them back into the battery supply chain as efficiently and economically as possible, thereby improving the carbon footprint of lithium ion batteries, making them cleaner in general,” said Roger Lin, vice president of global marketing and government relations of Ascend.

Through the hydro-to-cathode process, Ascend takes the spent lithium ion batteries and uses hydrometallurgy to extract the metals from their ores such as lithium, cobalt, nickel, and manganese. After this chemical extraction is complete, these elements are used to create brand new cathode materials, which essentially form the heart of lithium ion batteries, Lin said.

Rather than simply being recycled, Ascend is able to craft new, better performing, and chemically customizable batteries to suit the needs of electric vehicle manufacturers.

The sustainability benefits of this process are multifaceted. The manufacturing scraps, which would otherwise be in a landfill, are given new life while reducing the need for mining lithium from the Earth. Meanwhile, Ascend has positioned itself to supply and support the growing, green future of electric vehicles.

The proof of Ascend’s process is in the results of its business strategy which has exploded over the past year. In January, Ascend opened a $43-million, 154,000-square-foot facility in Georgia, capable of processing 30,000 metric tons of discarded lithium. This is just phase one of a plan that includes constructing an apex facility, which will transform this salvaged lithium into cathode materials on a massive scale.

While growing its domestic production capacity, Ascend is eying future commercial plants in Europe.

“What do we do with all the batteries at the end of life? And what do we do with all that scrap? Do we just throw it away and mine more? Or do we try to reclaim it, recover it, revive it, and return it back to the supply chain? Obviously, the latter is where we're focused,” Lin said.

2022 Manufacturing Excellence Awards

- Manufacturer of the Year: Catania Oils

- Top Product Design & Innovation: Burkart-Phelan, Inc.

- Workforce Development Award: Bristol Myers Squibb

- Green Manufacturing Award: Ascend Elements, Inc.

- Best Collaboration Award: Waters Corp.

- Manufacturing Champion: Jeannie Hebert

- Rising Star: Solvus Global

0 Comments