Essential manufacturing includes a wide spectrum of workers, ranging from those who produce medical supplies to those who support the agricultural market, and everything in between.

Get Instant Access to This Article

Subscribe to Worcester Business Journal and get immediate access to all of our subscriber-only content and much more.

- Critical Central Massachusetts business news updated daily.

- Immediate access to all subscriber-only content on our website.

- Bi-weekly print or digital editions of our award-winning publication.

- Special bonus issues like the WBJ Book of Lists.

- Exclusive ticket prize draws for our in-person events.

Click here to purchase a paywall bypass link for this article.

As unemployment claims skyrocket and business owners around Massachusetts shutter their doors in the face of the coronavirus crisis, one sector of the economy remains as busy: essential manufacturing.

Under an essential business emergency order announced by Gov. Charlie Baker on March 23 and modified on March 31, essential manufacturing includes a wide spectrum of workers, ranging from those who produce medical supplies to those who support the agricultural market, and everything in between. And, importantly, the order specifies essential manufacturers includes those who are part of the supply chain for other essential industries like transportation, energy and communications.

But as the coronavirus pandemic wears on, with few concrete indicators signaling how long the crisis will last, manufacturers are struggling with, perhaps above all else, the ambiguities inherent to the situation, said Kathie Mahoney center director for the Massachusetts Manufacturing Extension Partnership, the industry educational organization based in Worcester.

“It’s just the uncertainty of how long is this going to go? What do I do if someone gets sick? How do I protect my employees?” Mahoney said. “It’s all kinds of questions like that.”

As both the pandemic itself and the regulations put in place to help stop it change at a near breakneck pace, the ever-shifting landscape makes it difficult for groups like MassMEP to zoom out and assess the situation from a big-picture perspective, she said. At the moment, Mahoney said, MassMEP doesn’t have data regarding how many manufacturers have temporarily closed, whether because they are non-essential or for other pandemic-related reasons.

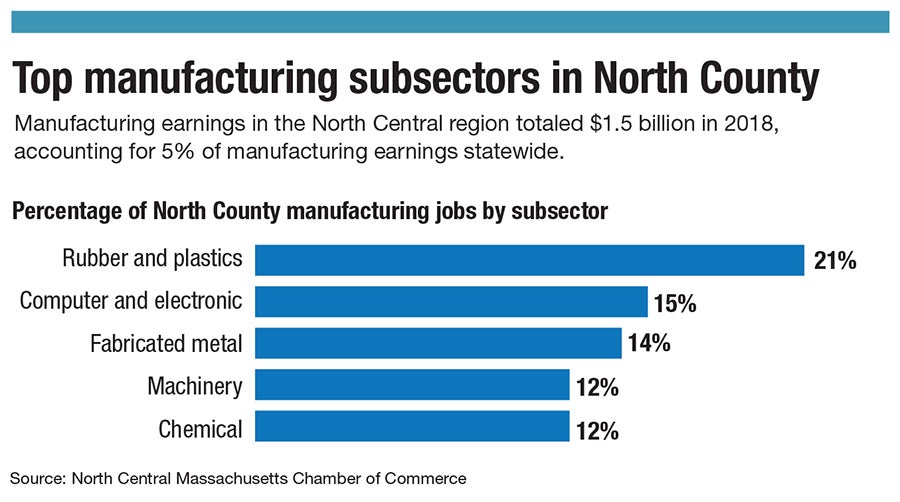

Roy Nascimento, president of the North Central Massachusetts Chamber of Commerce, echoed similar sentiments, noting that North County’s 450 manufacturers make manufacturing the region’s second-largest industry. But like Mahoney, he said it’s unclear how many have had to shut their doors under either Baker’s guidance or as a result of other coronavirus-related challenges.

“This has been a disruption,” Nascimento said.

Staying safe and essential

Both Mahoney and Nascimento report their respective organizations fielding questions from manufacturers regarding how to interpret the state’s essential manufacturing definitions, and in some instances, Nascimento said, asking for advice about how to apply for a waiver to allow non-essential manufacturers to continue operating.

But for at least some manufacturers, like Spencer-based FLEXcon, which is considered essential because many of its customers run essential businesses, and because the company produces pressure-sensitive film products used on, among other things, an array of medical equipment, operational questions have not so much focused on whether they are critical producers, but rather on how to keep staff safe during the coronavirus outbreak.

“We broke into three different teams: a containment team, a communications team and a business continuity team,” said Neil McDonough, CEO and chairman of FLEXcon Holdings. “And every morning there's a check in.”

While everyone who can work at home has been asked to do so, McDonough said FLEXcon has placed a significant emphasis on protecting the health of those employees required to be on-site in order for production to continue. This includes social distancing, as well as increased handwashing, and banning travel between FLEXcon’s various campuses, as well as between buildings, he said.

“We look at it as, if we're going to stay in operation for our customers producing [essential equipment], we have to make sure that we can stay in operation,” McDonough said.

The FLEXcon head thanked his lucky stars the company has had little to no supplier issues in the face of the coronavirus crisis, highlighting that most of its suppliers are based in the U.S. and remain operational – but even more so that the manufacturer has been able to stay open at all. Unlike the service industry or the public sector, he and his employees don’t have to interact with the general public and be scared every day.

“There are sectors of the economy much more difficult than manufacturing right now,” he said.

The long-term impact on manufacturing

As for how he thought the pandemic might impact FLEXcon’s operations in the long term, McDonough pointed to, among other things, potentially superfluous travel. Before the pandemic, he said, he estimated he was traveling 50% of the time. Now, he’s considering what and how work can get done without planes and hotel rooms.

“It’s going to effect how people approach business in the future, and in some very positive ways,” he said.

Looking forward to a time when the coronavirus crisis subsidies, Mahoney from MassMEP expressed optimism about the future of the state’s manufacturing industry.

“This is me personally: I think what's going to happen is that, I think, overall, the manufacturing economy is going to be stronger because of this,” Mahoney said. “What's going to happen on the other side of it is that there's going to be a demand to make more in the United States and not be reliant on overseas production.”

At the end of the day, she thinks the state government is handling the crisis in stride, and she urged manufacturing leaders to defer the bulk of their questions to the government’s COVID-19 portal. With all of the state and federal resources available for companies impacted by the crisis, she said, manufacturers who have closed will hopefully have their operations back up expediently, when all is said and done.