An assembly line of homes: Worcester firm sees factory-built apartment units as a potential gamechanger for region’s housing crunch

photoS | ERIC CASEY

Ron Bourque (right) and Ricky Carlos Martins founded Integrity Modular Design & Construction in Worcester in order to provide Massachusetts with local options for residential modular construction products.

photoS | ERIC CASEY

Ron Bourque (right) and Ricky Carlos Martins founded Integrity Modular Design & Construction in Worcester in order to provide Massachusetts with local options for residential modular construction products.

Homelessness is at an all-time high in Worcester County, according to data released in June by the Central Massachusetts Housing Alliance, as rent prices creep upward due to high demand and low vacancy rates. A draft of the City of Worcester Housing Production Plan for fiscals 2026-2030 says the city needs upward of 12,000 new housing units in order to meet demand over the next eight years.

While a number of large multi-family apartment projects continue to be built across Worcester and beyond, a factory on Southbridge Street could be key in unlocking a faster and more cost-effective way to fight the housing crisis: modular construction.

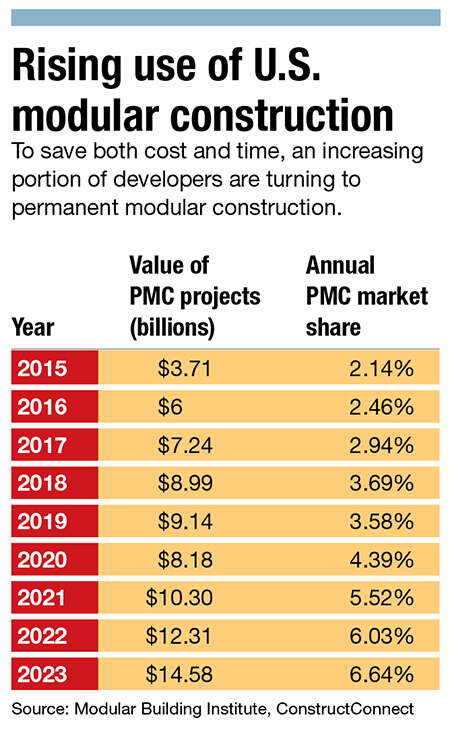

The technique opens up the possibility of assembling apartments off-site with a factory assembly line, then putting the project together on-site like a large-scale Lego kit, slashing both costs and construction times. Modular construction has come a long way over the past dozen years, with the growing industry behind the practice hoping perceptions and financing options can catch up with modern times to allow for this type of construction to become the norm.

“Many people still think it's the trailer with the wheels on it,” said Ron Bourque, CEO of Integrity Modular Design & Construction in Worcester. “That's actually a manufactured office, a different category than what people’s perception is. This is something very different.”

A longtime construction industry figure with experience in both architecture and project management, Bourque’s interest in modular construction began about 15 years ago, after the method was considered for a project he was working on. Looking into where modular units would come from, he noticed they were being produced in Ohio, Pennsylvania, and Canada.

“My first question to myself was: ‘Why not Massachusetts?,’” Bourque said. “We have the talent, we have the money, and we have the market. So why don't we have plants here?”

Save time = save money

After doing more research and watching the modular industry further develop, he founded Integrity Modular Design & Construction in 2023. Now confident in its proof of concept and with the necessary certifications, the firm is looking to ramp up its production capabilities this year.

Time is money, particularly in the construction industry, and perhaps the biggest benefit to modular construction is the elimination of variables like weather and its ability to allow construction of buildings to begin before or during site and foundation work. Between 60% to 90% of a modular project can be completed inside a factory, according to the nonprofit trade association Modular Building Institute, potentially shaving months off a project.

“The ability to produce it in a more streamlined fashion saves you square foot costs, because I don't have workers on site for 18 months,” Bourque said.

Constructing units from the comfort of a climate-controlled factory can be a benefit to workers, and it helps eliminate waste, saving both money and the environment.

“Unlike a traditional stick-built job site, where 15 to 20% of the raw materials brought to the job site end up in a Dumpster in the landfill, less than 1% of what's arriving ends up in a Dumpster in our factory,” said Scott Dennett, director of business development for Integrity Modular.

Other modular manufacturers build larger units, which require lots of paperwork and preparation to transport. Bigger units tend to flex when they are picked up by a crane to be put into position, said Bourque, complicating the construction process.

Seeking to overcome this potential obstacle toward wider adoption of modular construction, Integrity Modular is mostly focused on wood-framed units measuring 26 feet by 12 feet. This makes the units small enough to be pulled by pickup trucks if needed, avoiding the expensive process of getting approvals and escorts for oversized loads and allowing units to be taken under bridges and down narrow streets to their destinations.

The firm is in the early planning stages of projects in Whitman and Hopkinton and has been trading insights and knowledge with developers in Worcester who are considering the use of metal-based modular construction to build projects in Downtown Worcester, which are too tall for wood-based construction.

One longtime property developer who is considering utilizing modular construction for an upcoming project is Michael Ermani, who has been growing his Greater Worcester portfolio.

“You can get a lot more done inside a factory that's 70 degrees all year long, versus working in December, January, February when it’s freezing cold,” Ermani said. “The work goes so much faster. And then there’s the savings, because you can do it a lot quicker, you spend less and save money on interest.”

Permitting and financing

Despite perceptions, municipal building regulations typically are not an issue for modular construction, said Bourque.

“We actually have a third party that is an agent of the state that we work with, who ensures that we're doing everything that we're obligated to do,” he said. “That ensures that the quality of these units is much more robust. We overbuild a little bit so that we're able to completely finish them. When they leave the factory and they're placed on the unit, the only thing left to do is to bring in the appliances and do some finished painting.”

Financing these projects has been the biggest hurdle for modular construction to overcome. There's no collateral for the bank until the units are physically on the foundation, creating issues involving federal banking rules.

“It's just that they can't collateralize the loan because of federal regulations,” Bourque said. “So they've been hesitant, but they do see modular as a viable solution, especially with where we are with construction costs and labor shortages and everything else that's going to happen in the future.”

Integrated Modular has been in conversations with local financial institutions like Whitinsville-based UniBank to find ways to float a line of credit to bridge that gap.

Tackling homelessness

While Integrated Modular is mostly focused on residential construction, modular methods have been used across the country to build everything from cannabis dispensaries to fire stations.

The firm sees potential for modular units to be utilized as accessory dwelling units, said Bourque, which are now permitted by-right in Massachusetts thanks to a new law passed in February. Modular units can navigate the tight streets of places like Worcester and help avoid weeks of construction noise that might irritate neighbors.

While increasing modular construction in the state may have the knock-on effect of tackling the homelessness issue in Worcester County and beyond, Integrated Modular is exploring a more direct approach.

The company has been in talks with Mattie Castiel, commissioner for Health and Human services at City of Worcester, and former state Senate president Harriette Chandler to explore having the company construct modular homes for homeless veterans. Bourque is interested in finding ways for Habitat for Humanity to be able to utilize modular construction and his firm’s resources.

Eric Casey is the managing editor at Worcester Business Journal, who primarily covers the manufacturing and real estate industries.

0 Comments